Gulf Chemical is able to provide all types of custom machined parts with the DuPont Vespel engineering plastic.

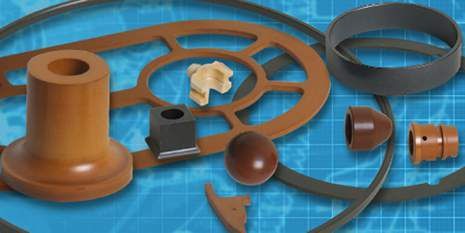

Vespel® Custom Plastic Parts

DuPont™ Vespel® custom plastic parts are specified where the material and design are key requirements for success in the application. Working with part designers DuPont optimizes design, material, and production method to get the desired end-use results. The manufacturing method is based on a number of considerations including part geometry, function and economics

Vespel® S Polyimide Family

Vespel® S products are highly durable polyimides used in demanding applications where exceptional thermal resistance (cryogenic to 349°C), low wear and/or low friction, strength and impact resistance are desired as custom parts or stock shapes.

Vespel® S polyimide family of parts and shapes with differing sets of attributes

The Vespel® S Family of products are highly durable polyimides and are used in demanding applications where exceptional thermal resistance, low wear and/or low friction, strength and impact resistance are desired.

SP-1

Unfilled. Superior wear and insulation properties with operating temperatures from cryogenic to 300°C. Low electrical conductivity. Highest elongation and purity of SP family. Available as custom parts or stock shapes.

SP-21

Graphite-enhanced with low-friction properties for use with or without lubrication in various applications. Available as custom parts or stock shapes.

SP-202

Conductive parts (<10E2 ohm) to help the elimination of static charge. Excellent wear resistance, dimensional stability at high temperatures and good machinability. Available as stock shapes.

SP-211

Lower coefficient of friction than SP-21 without lubrication in various applications. Available as custom parts or stock shapes.

SP-22

Minimal thermal expansion and dimensional stability for design flexibility. Available as custom parts or stock shapes.

SP-221

For highly specialized applications—against soft metals in “non-lube” conditions. Available as custom parts.

SP-2515

Low coefficient of thermal expansion, excellent wear properties and a low coefficient of friction for dimensional control. Available as custom parts.

SP-3

Used in vacuum and dry environments with low outgassing. Available as stock shapes.

SMR-0454

Graphite-enhanced for low friction. High modulus, low elongation, high compressive strength and low creep with less deflection under load. Available as custom parts.

ST-2010

Similar to SP-21 with improved toughness, higher elongation and better thermal oxidative stability. Better resistance to solvents, acids and bases. Available as custom parts.

ST-2030

Similar to SP-22. Found in applications in which low thermal expansion is more important than strength (which is slightly reduced). Applications may include bearings, bushings and washers. Available as custom parts.

SCP-5000

Unfilled SCP-5000 has better plasma resistance, dimensional stability and chemical resistance than unfilled SP-1. Like SP-1, SCP-5000 has good insulation. It has the highest elongation and purity of the SCP grades. Available as stock shapes.

SCP-5050, SCP-5009 & SCP-50094

Higher thermal oxidative resistance than SP polyimides with superior chemical resistance. SCP-5050 matches the CTE of steel. SCP-5009 and SCP-50094 approximates the CTE of aluminum. Available as custom parts or stock shapes.

SMP-40025

High modulus and low elongation provide dimensional stability at high temperatures and loads. Available as custom parts.

SF-0920, SF-0930, SF-0940

Superior thermal and electrical insulating properties. Unique polyimide foam has higher durability compared to low density polyimide foams. Available as custom parts.

Vespel® Uses and Advantages

Vespel® parts and shapes, both custom and stock, have been tested and proven effective in highly demanding applications around the globe. They are available in sheet, rod, tube, plaque, bar, disk, ring, ball, and custom machined parts.

Uses

- Bearings, bushings, insulators, seals, thrust washers, and wear rings

- Wear pads, wear strips, and tube clamps

- Thermoplastic injection-molded, assembled, and composite parts

- Test sockets and wafer guides

- Glass handling technology

- Wear components in centrifugal pumps

- Hydrocarbon, chemical, and water service pumps

- Potable water applications

Advantages

- Low creep and low out-gassing

- Lightweight yet handles high loads

- Chemical, electrical, wear, and thermal resistance

- Strength, stiffness, and dimensional stability

- Easy to machine and can be machined to very close tolerances

- Works well under hard vacuum, radiation, oxygen compatibility, cryogenic conditions, and exposure to flame

- Costs less to manufacture than ceramic